[Commitment to precision molding]

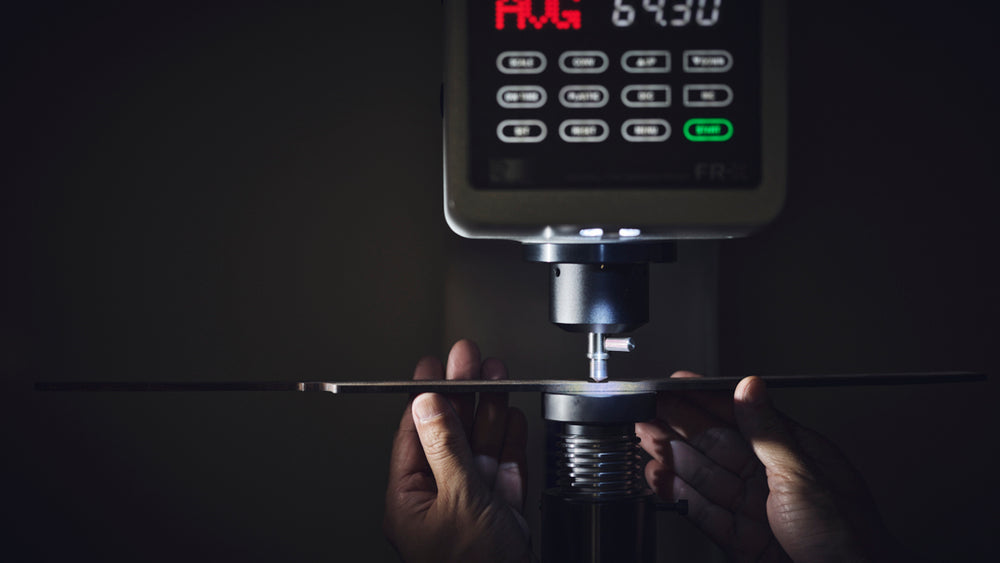

Nenohi's Japanese knives are subjected to "precision molding" that can only be done by ace rank craftsmen at the head office factory. The ideal Japanese knife shape is achieved by almost completely eliminating "distortions and unevenness on the flat/back surface" that cannot be corrected by the user in general. (The more accurately the user sharpens, the more the Shinogi line/back side shape is prevented from collapsing.)

In addition to the same precision polishing of the part that touches the hand when using it, such as the spine/heel, it has been polished round to achieve a stress-free grip and use.

Konohi's precision molding, which can be called "ultra-precision", enables practical use, which can be said to be the essence of Japanese knives, and this precise shape, which is practical to the limit, further enhances the beauty of the knife.