[Commitment to solid composition]

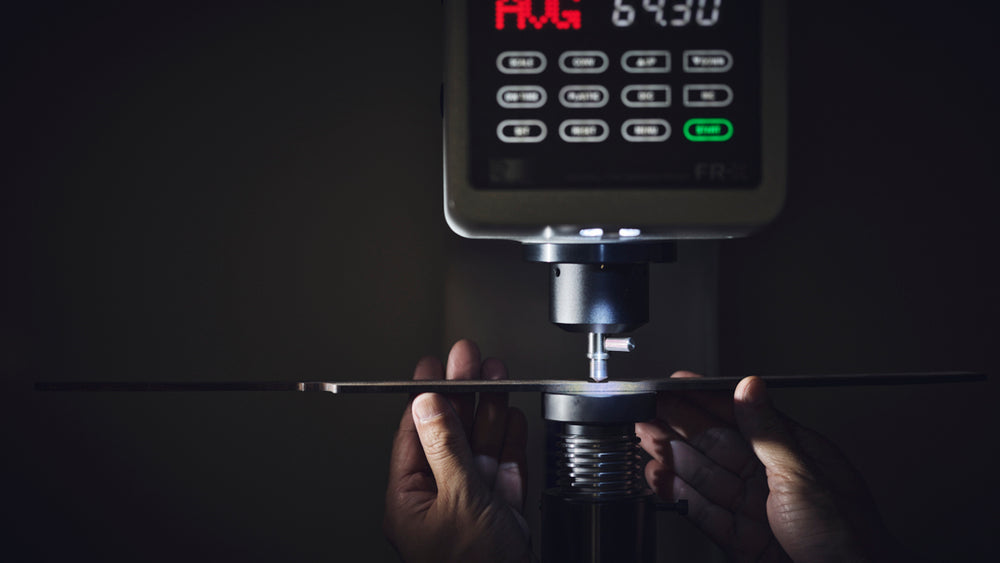

NenohiI specializes in knife construction using a single raw material known as "solid," which delivers superior cutting performance. (Solid construction)

This method, also called "hon-yaki" or "full steel," becomes extremely challenging when maximizing a knife's performance capabilities.

It brings out the full potential of the steel material and features remarkably minimal warping or bending during both production and use.

This solid construction achieves the demanding knife performance that Nenohi envisions.

It represents the pinnacle of knife-making that Nenohi has reached through accumulated research and refinement.