[Commitment to forged]

We employ "authentic forging (hand-finished forging)" to bring out the highest performance potential hidden within the steel (hagane).

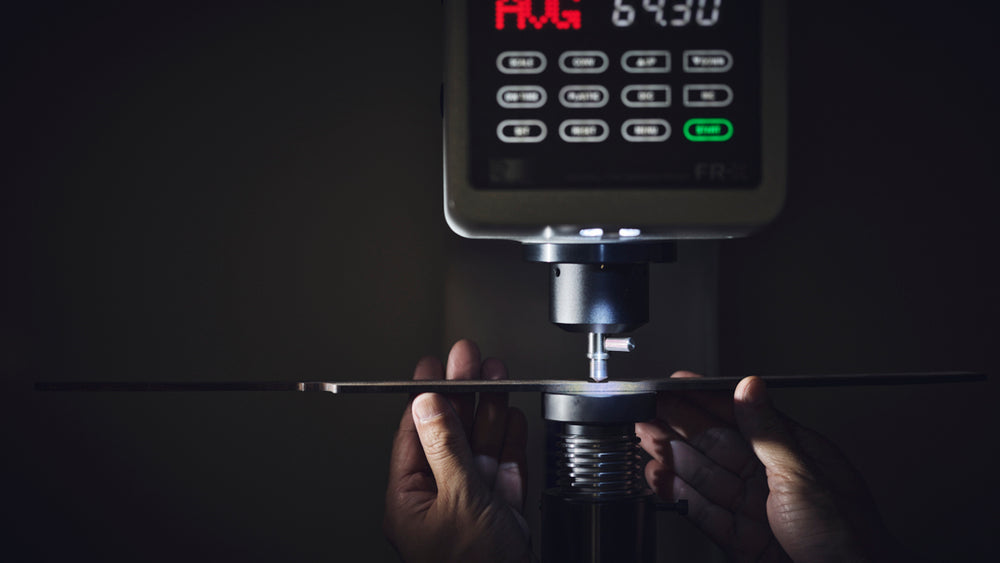

By carefully forging at low temperatures, we achieve the steel's inherent superior qualities such as sharpness, flexibility, and uniformity. Low-temperature forging is a labor-intensive and time-consuming method that limits production to only a small quantity of knives. However, Nenohi insists on low-temperature forging because it is a crucial process that significantly affects the knife's performance.